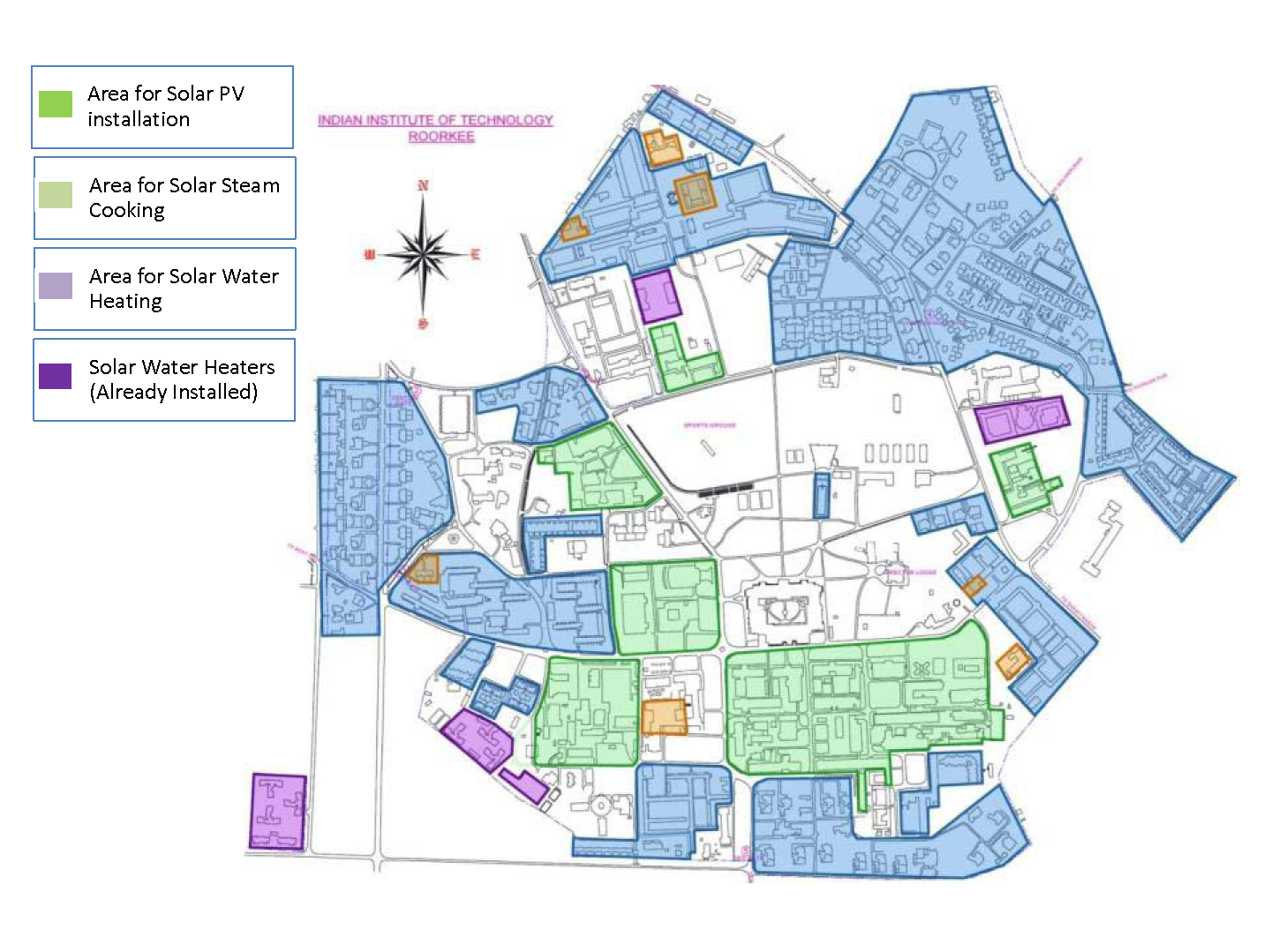

Solarification of Campus

Solar Photovoltaic Electricity Roof Top

| Cumulative Capacity | 1.819 MWp |  |

| Roof Area Covered | 22,000 sq m (27 buildings of all departments and units) |

|

| Technology Used | Polycrystalline | |

| Cost of the system | Rs. 14.14 crore | |

| First 5 year O&M cost | Rs. 13.75 lacs | |

| O&M cost 6 to 25th year | Rs. 3.49 to 15.55 lacs per year | |

| Unit Generation cost | Rs. 8.5 (without subsidy) Rs. 0.85 (with subsidy) |

|

| Electricity Generation | 30.8 lac units annual |

|

| CO2 Reduction | 2464 ton p.a. | |

| Contractor including O&M | Tata Power Solar | |

| Current Status | Order placed in Aug, 2013 and commissioned in March, 2014 | |

| Completed on | March, 2014 |

Solar Steam Cooking

| Cumulative Collector Area | 976 sq. m (using 61 collectors) |

|

| No. of buildings | 9 hostel mess | |

| Technology Used | Dish type parabolic solar concentrator | |

| Cost of the System | Rs. 2.14 crore including steam cooking vessels | |

| First 5 year O&M cost | Rs. 45,95,528 | |

| LPG savings | Approx 5,000 cylinders (14.2 kg) per year |

|

| CO2 Reduction | 234 ton per year |

|

| EPC Contractor | Taylormade Solutions | |

| Current Status | Order placed in Oct, 2013 | |

| Completed on | Feb, 2015 |

Solar Water Heating Systems

| Cumulative Capacity | 339,700 litres per day |  |

| Cumulative collector area | 5,547 sq. mt. (ETC) | |

| No. of buildings | 9 hostels, 1 guest houses, 12 residential areas covering all staff |

|

| Technology | Evacuated Tube Collector | |

| CO2 Reduction | 4297 ton per annum |

|

| Electricity Savings | 53.71 lac units per annum | |

| Current status | Order placed on Tata Solar Power March, 2014 |

|

| Completed | Jan, 2015 |