STP AT IIT ROORKEE CAMPUS

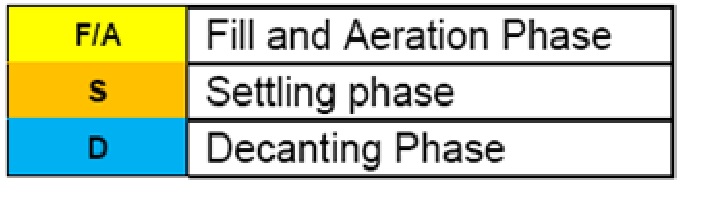

INTRODUCTION: A sewage treatment plant of capacity 3 MLD has been constructed at Solani Kunj near the C-class club. It is operational since Sept. 2019 and at present treating about 2MLD sewage. Some house connection of the sewerage system is under process and will be completed soon. The STP is based on the Sequencing Batch Reactor (SBR) process. It uses a fill and draw cyclical protocol inclusive of aeration and non-aeration sequencing to obtain biological treatment and sedimentation/clarification in the same basin. The system provides high-quality effluent for safe discharge or non-potable reuse with minimum space and power requirement. SBR CYCLICAL PROTOCOL: The treatment system consists of two basins, while one is in Fill & Aeration phase, the other is in Settling and Decanting phase. FILL & AERATION PHASE: Raw sewage is added to the basin and is mixed with sludge and aerated: 90 MIN SETTLING PHASE: All aeration and mixing is turned off, and the biomass is allowed to settle: 45 MIN DECANTING PHASE: Clarified effluent is removed, and biomass is wasted as necessary: 45 MIN

Typical SBR Cycle

Sewage Pumping Station

Screen & Grit Chamber

Sequencing Batch Reactor (SBR)

SBR Decanter PLC & SCADA based control

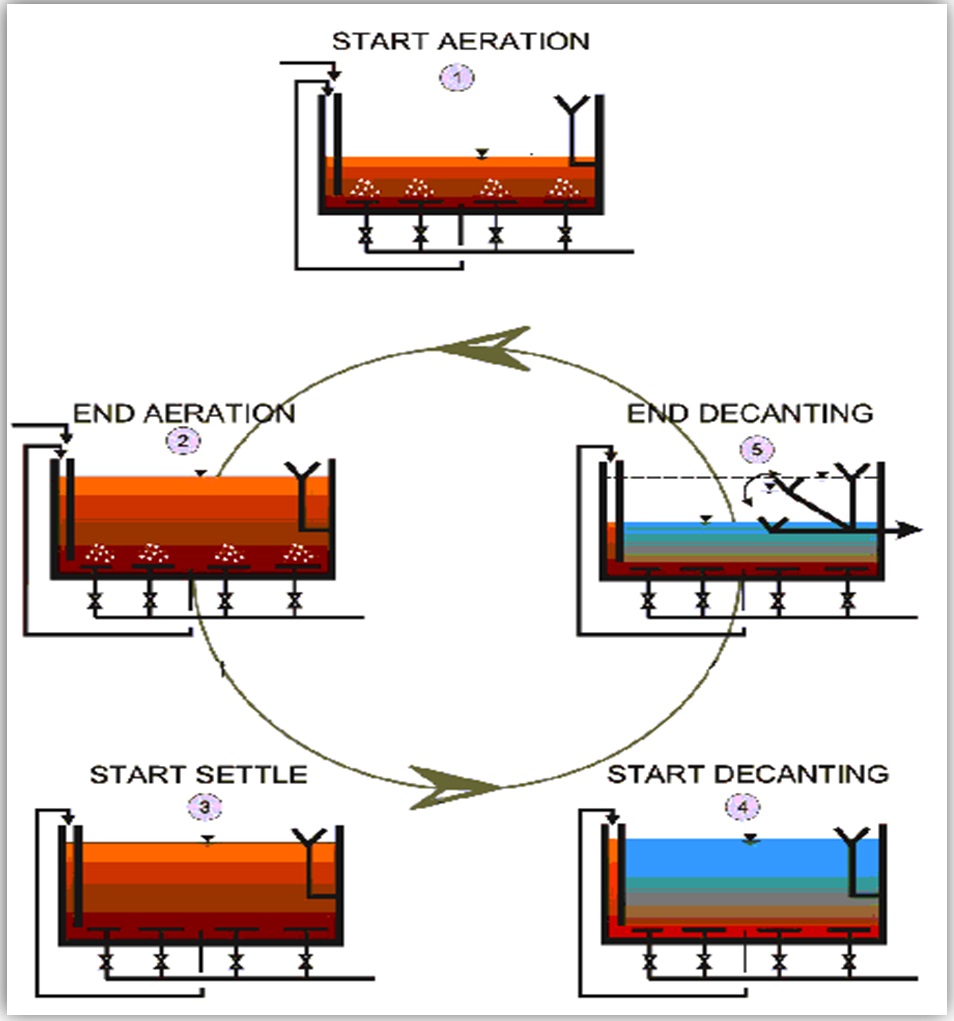

THE PROCESS: The unique feature of IIT Roorkee STP is the additional odor control and advanced tertiary treatment facility due to its settling in the residential area. The odour is controlled by the deodorization system for sump well and pre-treatment units. The STP is designed with an aesthetic appeal and all process units are housed in closed structure. State-of-the-art tertiary treatment (Fiber Disc filtration & UV disinfection) is provided for safe reuse of treated water for the horticulture in the campus and sludge as an organic manure.

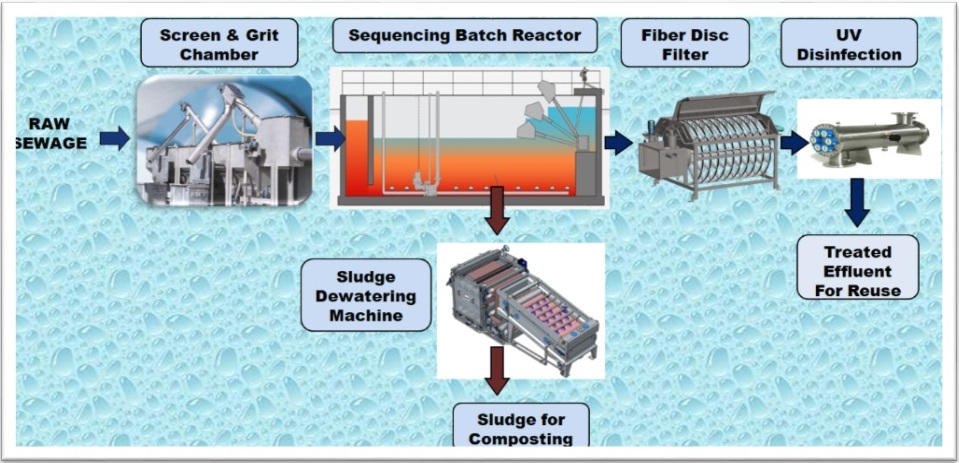

PERFORMANCE: The plant has shown excellent results since commissioning and has great flexibility to handle major influent load variations in monsoon and get down to very low values in the effluent. The treated effluent is crystal clear.

BOD removal Treated Effluent

Technical Data

Design Load

• Flow 3 MLD

• BOD 200 mg/L

• TSS 407 mg/L

• TKN 34 mg/L

• TP 7 mg/L

Effluent Requirement

• BOD ≤ 10 mg/L

• COD ≤ 50 mg/L

• TSS ≤ 10 mg/L

• TN ≤ 10 mg/L

• FC ≤ 100 MPN/100 ml

Fiber Disc Filter

UV Disinfection Unit

Sludge Dewatering Unit

External view from entry

Road side view